"We work to promptly eliminate global environmental pollution caused by disasters and wars both in Japan and abroad." |

Eco Factory Construction Project Launched

"We Are Launching an Eco-Friendly Intermediate Waste Treatment Facility!"

"We aim to eliminate dioxins and build an eco-friendly factory."

"Decommissioning of the Scallop Shell Waste Plant and Establishment of an Environmentally Friendly Intermediate Treatment Facility"

Purpose of Seeking Financial Support for Our NGO

Purpose of Seeking Financial Support for Our NGO

In May 2025, the dismantling of a seafood waste incineration plant previously operated by the Aomori Prefecture Scallop Waste Disposal Cooperative and decommissioned in 2021 was carried out using a robotic demolition method. With the support of our NGO, the project was conducted with a strong focus on technical precision and environmental conservation.

It is estimated that approximately 40 tons of dioxin contaminated residue will be discharged during the decontamination of the furnace body.

The national average cost for the final disposal of specially controlled industrial waste is approximately 40,000 yen per ton. In Akita Prefecture, under a prefectural government initiative, specially controlled waste generated within the prefecture can be disposed of for 13,000 yen per ton.

However, in Aomori Prefecture, disposal companies have quoted significantly higher prices around 220,000 yen per ton.

As a result, the estimated total cost for the disposal of 40 tons is approximately 8.8 million yen. Including transportation expenses, the total is expected to exceed 9 million yen.

Therefore, we have decided to seek support from companies and individuals across the country through a crowdfunding campaign.

As a goal for two years from now, this facility is expected to...

- Remove the incinerator and its flue, and construct a new intermediate processing facility for dismantling solar panels, which are expected to be discarded in large quantities in the near future.

- Recycle gypsum boards generated from future residential demolitions into soil improvement materials for agricultural use through intermediate processing.

- Utilize the surrounding land, purchased along with the factory, as a growing medium for seedlings to support forest conservation efforts.

At present, we are considering the above plans.

We believe it will be possible to return a portion of the profits generated from these facilities to those who have invested in the project.

We would be grateful for your support in funding the construction of this intermediate processing facility, and we hope you will join us in launching this unprecedented eco-friendly initiative.

For these purposes, we are planning to raise funds through crowdfunding.

Further details will be provided shortly, so we kindly ask for your patience.

If you would like to receive more information or verify the details, please contact us at the email address provided below.

Contact Email Address: pcpcm986@yahoo.co.jp

"An in-depth explanation of the background leading to the project's launch, along with the cost-reducing technologies and strategies implemented."

"An in-depth explanation of the background leading to the project's launch, along with the cost-reducing technologies and strategies implemented."

In Aomori Prefecture, a scallop waste incineration facility owned by a cooperative organization for fishermen, which was closed in 2023 , submitted a formal notice of closure due to the soaring cost of heavy oil, which made processing expenses prohibitively high.

Although this facility was operated by a fisheries cooperative and is no longer in use, the local government continued to impose an annual fixed asset tax exceeding one million yen, placing a significant financial burden on the cooperative members.

However, in order to formally dissolve the cooperative, it is necessary to first remove the dioxin contamination from the incinerator of this facility, dismantle the plant, and subsequently demolish the building itself.

However, the estimated cost of demolition exceeded 50 million yen, an amount far beyond what the 20 cooperative members could possibly bear.

In light of this, the head of the cooperative reached out to our organization which holds national certifications and equipment for the decontamination of dioxins and asbestos requesting that we purchase the land and buildings.

After two years of discussions, it was agreed that in April 2025 , all assets, including the registration fees, would be purchased by Mr. Kenji Fujibayashi, the Executive Director of our NGO.

Under normal circumstances, if this type of work were carried out by workers from ordinary companies in accordance with the provisions of the Industrial Safety and Health Act, it would be subject to various legal regulations, which in turn would result in extremely high decontamination costs.

However, our NGO possesses the capability to perform complete unmanned decontamination of hazardous substances such as asbestos and dioxins.

Cap Robot System

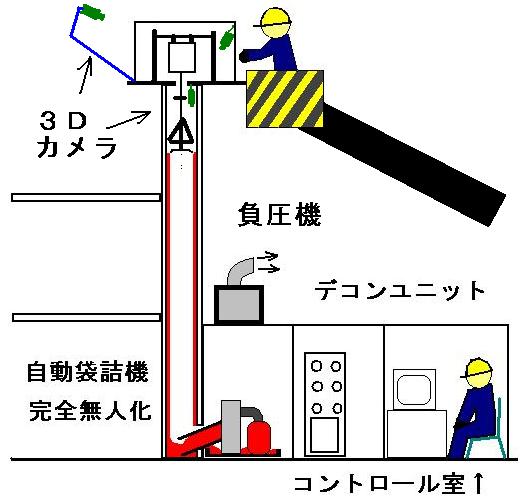

"Our NGO is equipped with the Cap Robot System, a fully automated and unmanned technology for decontaminating hazardous substances such as asbestos and dioxins."

As a result, since the work is carried out by the owner themselves, although worker's compensation insurance is not applicable, there are no restrictions on the construction process.

The decontamination work can be fully completed over approximately two years by three qualified directors.

This technology, owned by one of our directors, was used during the Great East Japan Earthquake to carry out fully unmanned decontamination operations at demolition sites in Fukushima and Miyagi Prefectures.

In Sendai, it was also employed for the removal and decontamination of Capstack materials in buildings owned by the Ministry of Finance.

This system has also been used at public facilities and schools throughout Japan.

Over the next two years, we will carry out fully unmanned decontamination of the incinerator, chimney, and other areas of concern for contamination, and proceed with demolition using robotic technology.

"An Overview of the Cap Robot Method"

"An Overview of the Cap Robot Method"

1. The Cap Robot Method

Normally, workers wearing heavy protective suits enter the inside of the incinerator to carry out decontamination work.

Even so, the work is carried out with the utmost caution, and periodic special health checkups designated by the government are conducted to ensure both the safety of the work and the health of the workers. For this reason, the construction requires a significant amount of time and cost to complete.

Even so, the work is carried out with the utmost caution, and periodic special health checkups designated by the government are conducted to ensure both the safety of the work and the health of the workers. For this reason, the construction requires a significant amount of time and cost to complete.

This is where the newly introduced Cap Robot Method comes in. As the name suggests, it is a method that allows robots to carry out the work, eliminating the need for workers to enter the interior of furnaces or chimneys.

Dangerous construction work is carried out by robots installed inside the furnace and chimney.

The workers monitor the progress of the work from a safe location (the control room) using 3D cameras.

2. Achievements of the Cap Robot Method

The Cap Robot Method was first put into practical use in 2010 at a facility in Shimonoseki, Yamaguchi Prefecture.

In the same year, it was also exhibited publicly at Tokyo Intech.

Additionally, in the year of the Great East Japan Earthquake, it was used at the request of a major joint venture (JV) for the demolition of a Ministry of Finance training facility in Sendai City.

Since then, it has been used in more than a dozen projects in Miyagi, Fukushima, Akita, and Iwate Prefectures, demonstrating its effectiveness.

3. Advantages and Disadvantages

The Cap Robot Method allows for efficient and safe operations. However, it does have some drawbacks:

Because the method is highly original and shortens the construction period, it is not profitable for construction companies.

Operating the machinery requires certification for handling contaminated materials after removal.

For these reasons, the method has not become widespread.

On the other hand, the advantages include:

Since workers do not enter contaminated areas designated under special laws for dioxins and PCBs, the method is exempt from the application of the Industrial Safety and Health Act.

In principle, there is no obligation to notify the Labor Standards Inspection Office.

Operators are not required to undergo special medical examinations (blood tests for one person alone can cost around 600,000 yen).

Because the goal is to carry out the work with a small team and at low cost, this method is the most essential one.

We plan to disclose all details to those who support this demolition project and to make the construction site open to the public during the work.